News List

Contact Us

Changsha Samy Instrument & Equipment Co.,Ltd

Wuhan Ande Corporation

Tel:027-8506 0791

Cell:0086 13873172353

What's app/Wechat:008613873172353

E-mail:samy@samycs.com

Skype:sunnyp16

LDMC-15 Automatic PLC Control with Up and Down lift lab nitriding furnace

Sources: Author:admin Release time:2020-12-23 16:32

LDMC-15 Automatic PLC Control with Up and Down lift lab nitriding furnace

Nitriding furnace introduce:

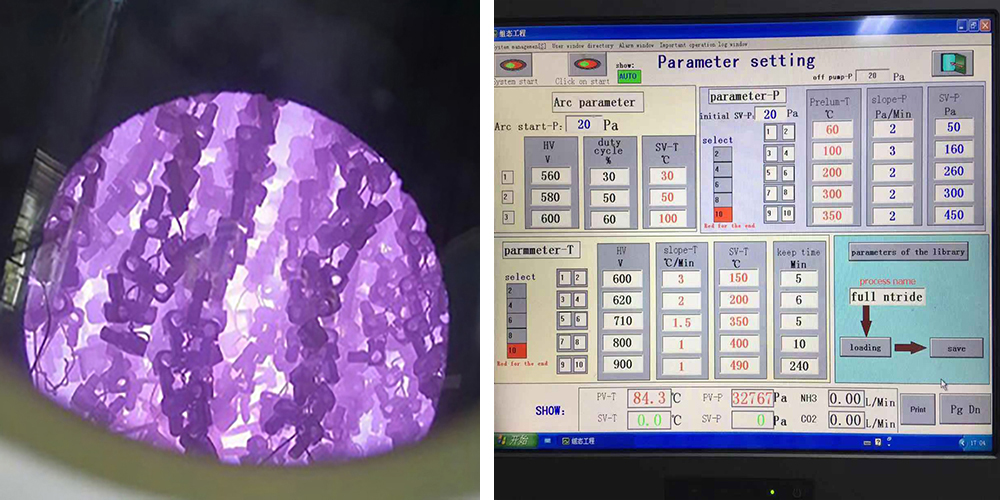

Glow ionic nitriding furnace includes ionic triding and lon-carbonitriding .glow ionic nitriding furnace can significantly enhances the surface hardness of steel parts,resistance to damage,fatigue and corrosion;because it has the advantages for energy saving, save gas, high efficiency, good quality, no pollution, etc. It has been applied widely in power, machine tools, petrochemical machinery, textile machinery, mold and other industries.

1.LD Glow Ionic Nitriding furnace Equipment

The traditional glow ionic nitriding furnace equipment,which is suitable for most work-piece ,is direct-current;Due to it’s features on technology,though pulse equipment is popular today,direct-current is still widely used.

2.LDMC Pulse glow ionic nitriding furnace

Pulse has rapid arc starting and permeating rate .The adjustable range of working air pressure is approximately at 20%-30% compare to the DC .And it is suitable for the complex workpieces which has high requirements of surface,many groove .it is frequently-used glow ionic nitriding furnace equipment nowadays.

3.LDMC Direct-current and pulse nitriding furnace

It is a Nitriding equipment which has the features for direct-current and pulse equipment.

4.LDF、LDMCF、LDZMF Auxiliary heating ionic nitriding furnace

Auxiliary heating glow ionic nitriding furnace which based on direct-current,pulse equipment and Dc pulse dual-use equipment added a resistance for auxiliary heating .It is operation simple and reliable ,and siutable for most work-piece especially light parts.

5.Ionic carburizing equipment

Ionic carburizing is new carburizing equipment ,it has the features for faster permeability(0.8mm/2h) and carburized layer of high quality.

6. Nitriding quenching furnace

With functions of ion carburizing and quenching vacuum.

Increase of superficial hardness;

Improved resistance to wear and tear;

Improved resistance to stress;

Less Friction;

Moderate resistance to corrosion.

From 0.10 to 0.5 mm

Due to gaseous nitriding, the product appears neat and in a shade of opaque light grey.

· Nitriding steels;

· Steel used for tools;

· Carbon Steels;

· Tempering Steels;

· Cast-steels

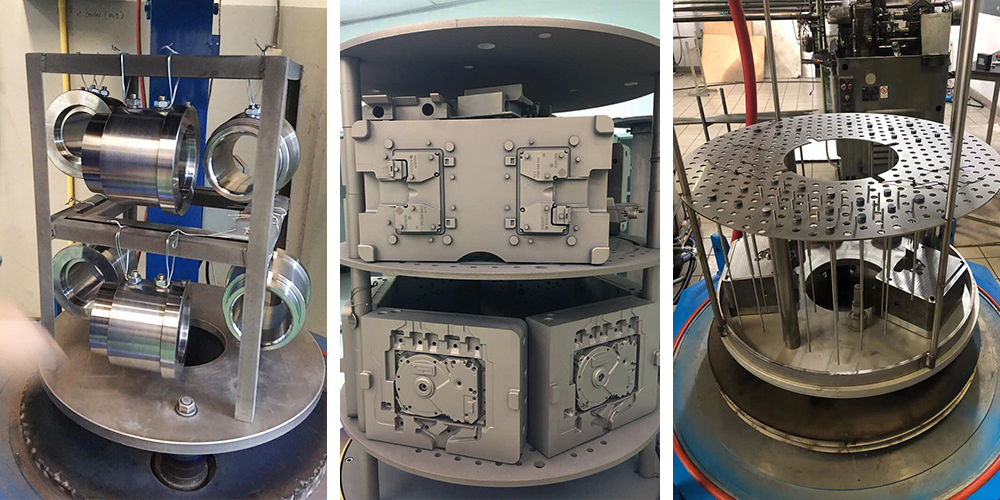

LDMC-15 Pulse ion nitriding furnace main parameters :

Model |

LDMC-15 Automatic Up and Down lift nitriding lab furnace |

Working chamber |

Ø400*500mm |

Max Working temperature |

650℃ |

Common working temp |

500±50℃ |

Ultimate vacuum |

≤6.7Pa/30Min |

Pressure rising rate |

≤0.13Pa/min |

Model |

LDMC-15 Automatic Up and Down lift nitriding furnace |

Maximum average output current |

15A |

Maximum peak output current |

30A |

Max nitride area |

60000c㎡ |

Max loading weight |

100kgs |

Output supply |

30KW |

Output status |

Rectangular web |

Frequency |

1000HZ |

The arc velocity |

≤20 Microsecond |

Control method |

Fixed frequency widt |

Occupy space rate |

0-85% continue adjustable |